Air motors, by design, are intrinsically non-sparking because they use compressed air as their energy source. In addition to being a much more economical option than their explosion-proof electrical counterparts, they can also operate safely in wet or corrosive environments. Electric explosion-proof motors have a tight fit between mating parts to ensure the integrity of the explosion-proof enclosure.This can lead to an accumulation of moisture inside the motors due to condensation. Care should be used when selecting an electric explosion-proof motor, especially when installed outdoors and on intermittent duty.

The weight of equipment is largely determined by the motor. Air motors are more lightweight than their electrical counterparts. This is largely due to the fact that the power is not actually generated at the air motor.

One of the main problems in industries where lots of electric motors work simultaneously is the peak current. This will become more severe when lots of starting happens. Using air motors can help solve this issue.

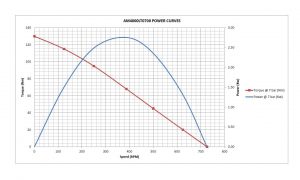

Air motors have a distinct advantage in area of torque, because they dynamically load torque. Essentially, an air motor adjusts its torque output to match the necessary torque requirement of the application. The most common air motor manufactured by Vayu Pneumatics is a rotary vane motor. Rotary vane motors are simple in design and are usually available in small sizes 1/10 to 10 hp, with a maximum operating pressure of 10 bars.This type of air motor uses stored energy in the form of compressed air, which enters the sealed motor chamber and exerts pressure against the vanes of a rotor.This action causes the rotor to turn at a high speed.The compressibility of the air is the key to the dynamic torque loads available through a rotary vane motor. As the output shaft is opposed by the torque of an application, the vanes are slowed, thus compressing the air.This compression increases the applied torque.The motor continues to provide increased torque until it stalls, and then it maintains its stalled condition without damaging the motor. As the load is decreased, an air motor will increase speed and decrease torque to match the load.

One of the benefits of air motors is that they can achieve variable speeds by adjusting the air control valve. With an electric motor, there are variable speed control options available, but they substantially increase the price of the motor being offered. But it should be noticed that decreasing air supply will also result in air motor power and torque decrease.